Extend the Life of Your Motors with Expert Rewinding Solutions

Electric motors are essential in industries ranging from manufacturing to HVAC and agriculture. But when motors fail, replacement isn’t always the best option. Instead, motor rewinding services offer a practical, cost-efficient, and eco-friendly way to bring your motor back to peak performance.

This guide covers everything you need to know about motor coil rewinding, including how it works, when it’s needed, and why it’s a smart choice for your business or equipment.

What Is Motor Rewinding?

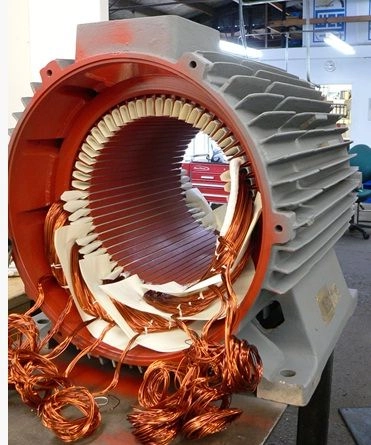

Motor rewinding, also known as stator rewinding or coil re-insulation, is the process of removing and replacing damaged or deteriorated windings in electric motors. It’s commonly used to restore the performance of AC and DC motors that have suffered insulation failure, burnout, or electrical faults.

The Motor Rewinding Process Involves:

- Disassembling the motor housing

- Stripping the old copper windings

- Cleaning the stator core

- Installing new copper coils with upgraded insulation

- Reassembling and testing for functionality and safety

The result is a motor that operates with near-original efficiency, often at a fraction of the cost of purchasing new.

When Is Motor Rewinding Needed?

Over time, electric motors degrade due to heat, overload, poor maintenance, or simply age. Here are the most common signs your motor might need rewinding:

- Sudden motor failure or shutdown

- Overheating or thermal damage

- Fluctuating voltage or power loss

- Burnt smell or visible insulation damage

- Failed insulation resistance or continuity tests

- Strange noises or irregular vibration

Key Benefits of Motor Rewinding

Choosing motor rewinding over full replacement offers numerous benefits:

* More Affordable Than Replacement:-

Rewinding is typically 40–70% less expensive than buying a new motor, especially for large industrial units.

* Environmentally Friendly:-

It reduces electrical waste and keeps usable motors out of landfills.

* Restores Original Function:-

A properly rewound motor performs as well as—or sometimes better than—a factory-new unit.

* Reduces Downtime:-

Rewinding can often be completed faster than sourcing and installing a new motor.

* Customizable:-

Rewinding allows for modifications to suit new voltage, frequency, or load requirements.

How to Choose a Reliable Motor Rewinding Company

Before handing over your motor, be sure the service provider meets the following criteria:

- Certified technicians with experience in electric motor repair

- Advanced testing tools (such as surge testing, megohmmeter insulation testing)

- Use of high-grade copper and insulation materials

- Capability to rewind both AC and DC motors

- Quick turnaround time and emergency service options

- Warranty and documentation for work done

Always ask for a full report of the rewind process and performance test results.

Request a Quote for Motor Rewinding Services Today

At GURU NANAK ENGINEERING WORKS, we specialize in professional, high-quality motor rewinding and refurbishment services. Whether it’s a small fan motor or a large industrial drive, our team ensures precision, reliability, and efficiency with every job.

- Industrial motor rewinding

- Energy-efficient motor upgrades

- Pickup and delivery available

- Free diagnostics and consultation

👉 Call us now at 98168-21644 or request a quote at https://gurunanakengworks.com/